Purpose of a refrigeration system –UAE | Viessmann

Refrigeration the process of removing heat from a confined space or object for the purpose of lowering the temperature. In industrialized nations and affluent lands in developing lands, refrigerators are primarily used to store food at lower temperatures, thus preventing the destructive action of bacteria, yeast, and fungi. Many perishable products can be frozen, allowing them to be stored for months and even years without the slightest loss of nutrients or taste or appearance. Air-conditioning, the use of refrigeration for comfortable cooling, is also widespread in developed countries.

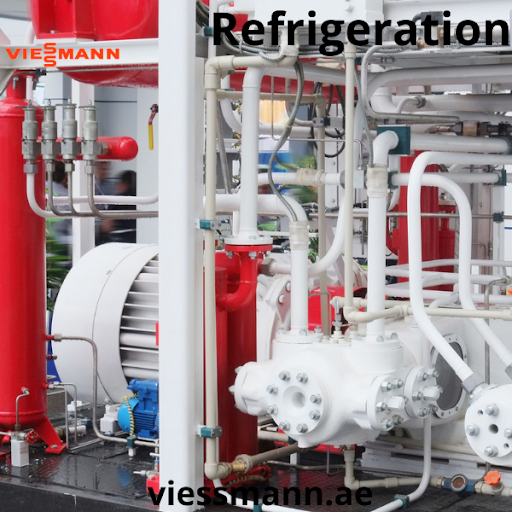

The basic components of a modern vapor pressure system are a compressor; condenser; expansion device, which may be a valve, capillary tube, engine, or turbine; and evaporator. The gas cooler is first compressed, usually with a piston, and then pushed through a tube into the condenser. In a condenser, a rotating tube containing vapor passes through a circulating air or bath water, which releases the heat energy of the compressed gas. Cool is transferred through an expansion valve to the lowest pressure point; as the vapor grows, it absorbs its expansion energy into the surrounding or central contacts. Evaporators can either cool the space directly by allowing the vapor to come in contact with the cooling system, or they can do this indirectly — that is, by cooling the second object such as water. In most home refrigerators, the coil containing the evaporator comes in direct contact with the air in the dining area. At the end of the process, the hot gas is drawn into the compressor.

Continuing the competitive climate of commercial refrigeration can be a challenge. However opportunities are increasingly available for refrigeration manufacturers who are keen to keep an eye on current market opportunities, including the re-branding of vaccine refrigerators and commercial refrigerators using the latest low-cost (low-GWP) refrigerators to reduce environmental emissions.

Refrigeration certificate requirements can be complex and if you want to keep refrigeration concepts developing through a product development cycle, you need a refrigerator testing specialist who knows the way forward - which includes all the latest refrigeration certification requirements.

Choosing UL to be by your side during a commercial refrigeration test and certification cycle can help you save time that may be unnecessarily lost in redesign, allowing you to find a place and meet market goals.

We provide complete refrigeration compliance solutions and product certificates that include:

· Commercial and commercial refrigerators and refrigerators.

· Condensing units, monoblocks and walk-ins.

· Sales & Disposal (sales equipment, dispensers, beverage coolers).

· Ice makers (ice cream, ice cream).

· Wine coolers and chillers.

· Policy adherence.

We will compare what you are already familiar with such as space temperatures and common components of basic AC systems with those of commercial refrigeration systems. We will inspect evaporators, condensers, compressors, meter measuring devices, controls and utensils, as well as refrigerators commonly used in commercial refrigerators. We will review keywords. At the end of this tutorial we will introduce a system problem solving, giving you the opportunity to put your knowledge into the 9 most common system problems. You will also understand when to use TROT (Rule Six) without the manufacturer's recommendation.

Comments

Post a Comment