Get the best service provide Steam Boiler - UAE - Viessmann

Steam boilers that produce steam power are pressed by heating water in their boiling area using a combustible fuel source. How water is heated depends on the fire tube or water boiler. The main difference between the two can be found in their names. In a fire tube boiler, a burning oil source is contained inside a tube surrounded by a vessel full of water. The tube gradually heats the surrounding water, eventually producing steam. In a water tube boiler, water is contained within multiple tubes, and heat from combustible fuel is used outside the tubes to produce steam.

Compression vessel: A pressure vessel contains gases or liquids at high temperatures, usually under high pressure. In a boiler, the pressure vessel is made of solid material, usually steel.

Burner: The burner provides boiler heat by heating gasoline and oxygen. Fuel sources include natural gas, low-pressure propane, oil number 2, coal and other fuels.

Tubes: For water boilers, the inner tubes of the boiler contain water and are heated outside. In fire tube boilers, flammable gas passes through one or more tubes, heating the water around the tubes.

Economizer: An economizer is a heat exchange system that transmits heat energy otherwise it is lost in exhaust gases and uses that energy to heat water into the boiler. As a result, less energy is required to heat the incoming water, making the boiler more efficient.

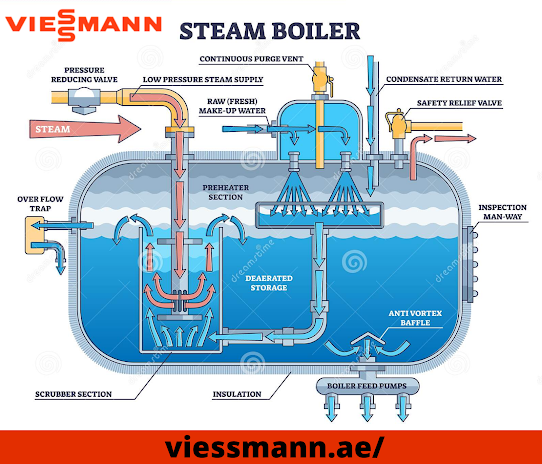

Deaerator Tank: Deaerator water tanks use pressure and heat to release oxygen and other soluble gases (especially, carbon dioxide) in boiler water. Soluble oxygen and carbon dioxide can cause severe corrosion of the boiler.

Heat Exchanger: Heat Exchanger: A heat exchanger that transfers heat from one object to another unless those elements are directly connected. In a boiler, the heat of the hot gas is transferred to the water using a heat exchanger.

Control Panel: The control panel enables operators to control steering settings such as temperature and pressure. Trade and industrial boiler control panels include detailed analysis.

Feed water Tank: A water supply tank is a collection tank that provides water used for boiler to make steam. A feed water tank is where fresh water is collected and thrown into a boiler. Boiling chemicals that release oxygen and protect the metal inside the boiler are injected and mixed inside the feed water tank. Utilities with condensate recovery lines can collect condensate water in a garden that falls below the boiler point and is returned to the system to retrieve clean water.

Fire System: The combustion system works by combining air and fuel and then combining the mixture to produce heat. Ensuring proper air balance in fuel is an important part of the boiler combustion system.

Reverse Osmosis System: Reverse Osmosis operates by using a high pressure pump to increase pressure on the RO water side and forcing water into the RO fluid that does not turn slightly, leaving almost everything (about 95% to 99%) impurities. melted behind a stream of dumping.Chemical Monitoring Systems: Carefully added chemical additives can improve boiler performance.

Viessmann offers coil type boilers at a range of 50 to 850 kg steam per hour. The coil type boiler produces steam instantly and is very easy to install and operate. These boilers are safe, reliable and designed to use a wide range of liquids and gas fuels including heavy oil, light oil, gas, and two fuel options. Stigmatic is a reliable, fast-packed generator suitable for smoke or hot water needs. It is a seamless integrated solution to reduce operating costs for small heating loads, rather than expensive electrical systems. The large diameter of the compression parting tubes and the filter reflecting is specially designed to detect mud or rust, to prevent coil congestion, thereby reducing the operating time of the boiler. use. The heat source for modern boilers is usually electricity or gas. The boiler can be a 'closed' system, where 100% of the system is recycled in a liquid state, to be recycled and reused, or it can be a 'open' system, where steam is allowed. Escape, which requires the boiler to be constantly supplied with water.

Comments

Post a Comment