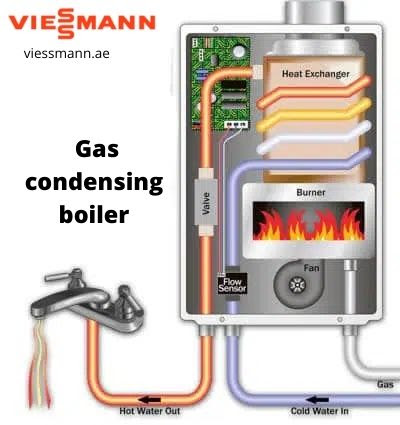

Gas condensing boilers system - UAE- Viessmann

Gas condensing boilers, called “condenser boilers”, have been compulsory in Ireland since 2005 and continue to be a contender for the domestic energy market. In this guide, we will explore everything you need to know and more about summary boilers. What is different about a conventional boiler? Are they right? How much do they cost, then, are they worth it? Prices for condensed oil boilers vary widely. The price will initially depend on the current system of your home, such as if you have a combo, a standard boiler or a system. It is much easier and less expensive to install an existing boiler and install the same type of billing system. From there, you will have to look at the different types of thick boilers. Whether or not conventional boilers are suitable to have or not will depend on the individual situation and the budget you have. Let’s weigh the pros and cons of keeping your steam boiler comparing to switching to a different option.

Condensation technology is currently spreading rapidly, not only to reduce environmental impact (-75% NOx and CO2 emissions) but also to reduce the use of boilers that accept this type of technology. In fact, using boiler condensing can effectively reduce gas consumption by up to 35% compared to a conventional boiler, which automatically translates into saving for the end consumer. Choosing a boiler condensing is the best way to save money and protect the environment.

The condensate produced is slightly acidic (3-5 pH), so suitable materials should be used in areas where the liquid is present. Aluminum and stainless steel alloys are widely used in high temperatures. In low temperatures, plastics are more expensive (e.g., UPVC and polypropylene). [1] The production of condensate also requires the installation of a condensate water drainage system to change the temperature. In standard installations, this is the only difference between a thick and a small boiler.

For economic production of a coarse boiler temperature (and for the device to be controlled during installation), a small effective output size is preferred. This method has resulted in high-temperature heat exchangers, which often require a combustion fan to move products along narrow paths. This also had the advantage of providing flue system power as the exhaust flammable gases are usually below 100 ° C (212 ° F) and, as a result, have a near-air congestion, with low boomancy. The fan helps to pump out exhaust gas.

Efficiency -

One reason for the decline in efficiency is that the design and / or use of a heating system provides return water (heat transfer fluid) to a boiler above 55 ° C (131 ° F), which prevents significant overheating in the temperature change. Better education for both suppliers and owners can be expected to increase efficiency in reported laboratory values. Natural Resources Canada [7] also suggests ways to better utilize these boilers, such as integrating space with water heating systems. Some boilers (eg Potter ton) can be switched between two flow temperatures such as 63 ° C (145 ° F) and 84 ° C (183 ° F), only the former "fully compliant." However, boilers are usually installed with a high automatic flow temperature because the domestic hot water cylinder is usually heated to 60 ° C (140 ° F), and this takes a very long time to achieve a flow temperature of only three degrees above. However, even partial thickening works much better than conventional boilers.

Gas condensing boiler many non-melting boilers can be forced to slow down using simple control changes. Doing so will significantly reduce fuel consumption, but will quickly destroy any soft metal or ordinary iron parts of the boiler with high temperatures due to condensate corrosion. For this reason, high-density boiler heat exchangers are made of stainless steel or aluminum / silicon alloy. Outer stainless steel economizers can be reassembled into non-rotating boilers to achieve optimal efficiency. Temperature control valves are used to integrate the hot water supply provided to be recovered to avoid hot shock or congestion inside the boiler.

Comments

Post a Comment